In our bustling global market, your supply chain efficiency can make or break profits. As businesses grow, challenges in buying, storing, and shipping amplify– with costs that can spiral beyond your control. Fortunately, with smarter supply chain strategies, you can turn this maze into a strategic advantage and reduce logistic costs.

Imagine having tried and tested strategies at your fingertips. Solutions that have been battle-tested by successful enterprises are tailored to give you a clear roadmap.

In this guide, we're unpacking 5 game-changing approaches to slim down those stubborn logistics and supply chain costs. From lean inventory models, optimized freight options, and dynamic pricing, these strategies will put you on the fast track to lower costs and higher profits.

Let’s get started.

What Are Logistics Costs?

Logistics costs cover all expenses tied to moving products within your supply chain. Think of it as the total price tag you get when you move your product from point A to point B.

These include both typical and indirect costs:

- Indirect costs: inventory carrying costs and tied-up capital in unsold goods.

- Typical costs: transportation, warehousing, packing, customs duties, and returns processing.

Logistics expenses typically make up around 10% of business sales which highlights their major role in profitability. When you know your logistics costs, you can choose the best suppliers, decide on transportation methods, and find the right storage solutions. Ideally, you want everything to run smoothly and still save money along the way.

So what affects logistics costs?

6 Factors That Affect Logistics Costs

On a global scale, logistics expenditures constitute an astounding 10-15% of the total world GDP. However, this percentage isn't uniform across the board and can vary based on factors like the economic development level and the economy’s orientation.

To give you some perspective, an economy anchored in natural resource extraction will likely face heftier logistics costs compared to one that's more service-oriented. Let's unpack the 6 key elements that can either be a boon or a bane to your logistics budget.

1. Labor Costs

Your logistics team is vital, but their salaries, benefits, and training can add up. The overheads, the managerial aspects, the IT expenses - they all fall here. From processing orders to managing the logistics workforce, these costs are hidden but play a vital role in the logistics budget.

Fluctuating labor markets can make staffing costs unpredictable. Consider how the holiday seasons demand extra hands on deck, causing higher expenses.

During peak holiday seasons, Amazon hires tens of thousands of temporary employees to meet increased demand. This labor cost is planned for, but it still spikes during these periods. Knowing when you'll need more or fewer staff during peak and quiet times can help you handle labor costs better.

2. Transportation Costs

The choice between trucking, airfreight, rail, or sea makes a difference. Each mode has its cost dynamics and transit times. They account for a whopping 58% of logistics costs. These charges aren't limited to just fuel and maintenance.

They include everything that is involved in the operations and maintenance of transportation modes and terminals throughout the supply chain. It's the money spent moving goods from manufacturing hubs to distribution and consumption points.

Take FedEx, for example. They have various transportation modes like trucks, airplanes, and trains. They decide the best and cheapest way to ship by looking at what items need to be delivered, where, and how quickly. They then pick the best delivery method.

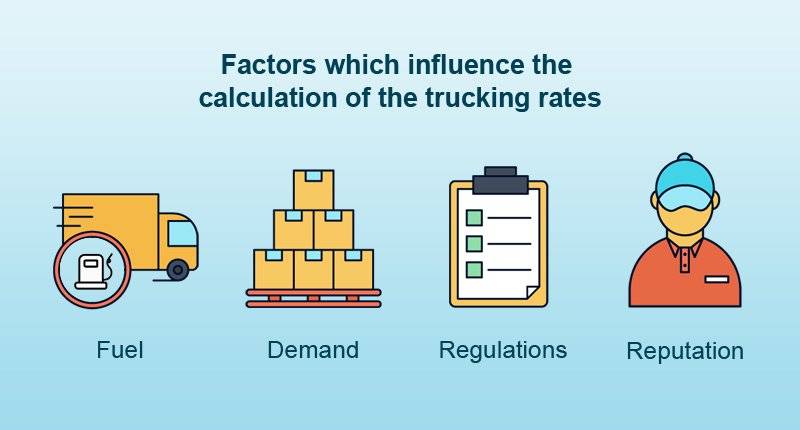

3. Fuel Costs

Anyone keeping an eye on global news knows fuel prices are always on the move.

Fuel costs can change suddenly, often driven by international political agendas, acts of nature, or economic states. A sudden spike in fuel costs can balloon your transportation expenses.

Many airlines use fuel hedging to protect against fluctuating fuel prices. They essentially bet on future prices to avoid being caught off guard by sudden spikes. You can apply similar strategies in logistics to stabilize fuel costs.

4. External Factors

The broader business landscape has its say. Trade regulations, customs duties, and even geopolitical events can throw a wrench into your logistics budget.

Factors like establishing a new presence in a different market can also play a role. When considering expansion or rebranding in response to market conditions, having the right business name ideas can make a significant difference in how smoothly these transitions occur.

For instance, when Starbucks first entered China, they adapted their name to Xīngbākè, which not only sounds similar but also conveys a positive image. This strategic naming choice helped with their smooth entry and acceptance in the Chinese market.

5. Inventory Carrying

Taking up about 23% of the logistic pie, these costs deal with maintaining inventory in a warehouse. This involves holding costs like labor, insurance, depreciation, and even obsolescence chances.

Additionally, this category covers physical goods management, including tasks like packaging and labeling. The variable cost nature often means they're pegged as the inventory value’s percentage.

6. Warehousing Costs

Location is crucial. At 11%, these fixed costs come from owning or leasing warehousing space. The costs here span from maintenance to utilities. Interestingly, they stay stable despite inventory volume. Prime city spots cost more than the outskirts.

Additionally, the storage type (cold, ambient, secure) and the time length you need it for matters.

Take Walmart, for instance. They strategically place their distribution centers to minimize transit times to their stores. However, they often opt for locations that balance cost and convenience, keeping warehousing costs down while still maintaining a robust supply chain.

Being proactive in understanding these is a shield against unforeseen expenses. Keep an eye out, plan and your logistics budget will thank you.

But what if you could do more than just monitor? Let's explore concrete steps you can take to optimize further and reduce those costs.

5 Strategies To Reduce Your Logistics & Supply Chain Costs

In the intricate supply chain management dance, keeping logistics cost reduction ideas under control while maintaining customer satisfaction is the ultimate goal. But how do you trim the additional costs without compromising on quality or delivery speed?

Dive into these 5 key strategies, each aimed at giving you the tools and insights to streamline your supply chain operations logistics and make your supply chain leaner, meaner, and more cost-effective.

I. Optimize Transportation Modes & Routes

Transportation costs often begin with how you move goods. Choosing the best transportation companies greatly affects shipping costs. Consider consolidated shipments to ensure customer expectations are met without inflating distribution costs.

Routing plays a massive role in transportation logistics costs. It's not just about delivery routes; administrative costs and ensuring proper business processes come into play.

Start by understanding each transport mode’s strengths and weaknesses. For instance, while trucks provide flexibility for short to medium routes and quick deliveries, trains can handle larger volumes over longer distances with greater potential cost benefits.

Sea freight might be slower, but it’s unbeatable for bulk international shipping. Selecting the right mode can balance cost with efficiency. For those who specialize in specific niches, like reselling, understanding transportation efficiency becomes even more critical.

Sneaker reselling, reselling communities, and especially reselling Discord communities thrive when the logistics behind them are robust.

Routing also plays a massive role in logistics costs. It's not as simple as picking the shortest path; other factors come into play, like ensuring that the paperwork, such as the crucial bill of lading, is spot on. Missing or incorrect documentation can derail even the most optimized transport plans.

Understanding traffic patterns, seasonal factors, potential road disruptions, and even identifying optimal fuel stations can significantly impact efficiency.

With today’s technology, sophisticated route optimization software aids in making these decisions, enabling real-time adjustments to adapt to changing conditions on the ground.

Consider Walmart, the retail giant. They efficiently manage the largest private fleets in the world. Through strategic transportation mode selection and optimized routes, Walmart reduced empty truck miles by over 15% in recent years.

Their advanced transportation management system allows them to adjust routes in real-time, highlighting technology’s profound value in route optimization.

External factors, such as fluctuating fuel prices, new road developments, or even shifts in market demand locations, warrant constant evaluations—periodic reviews help in staying adaptive and cost-effective.

II. Lean Inventory Management

Inventory costs often represent a substantial business capital chunk, and managing it smartly can save significant money.

A balance between raw material availability and warehouse space reduces costs. The density in bins and storage density in a storage space are also important considerations. Managing inventory levels correctly can avoid overstocking and save on storage costs.

Foremost, accurate inventory forecasting is crucial. By analyzing historical data, market trends, and even seasonality (like winter clothes demand during cold months), you can better predict your inventory needs. This not only avoids overstocking, which ties up funds but also prevents understocking, which can hurt sales.

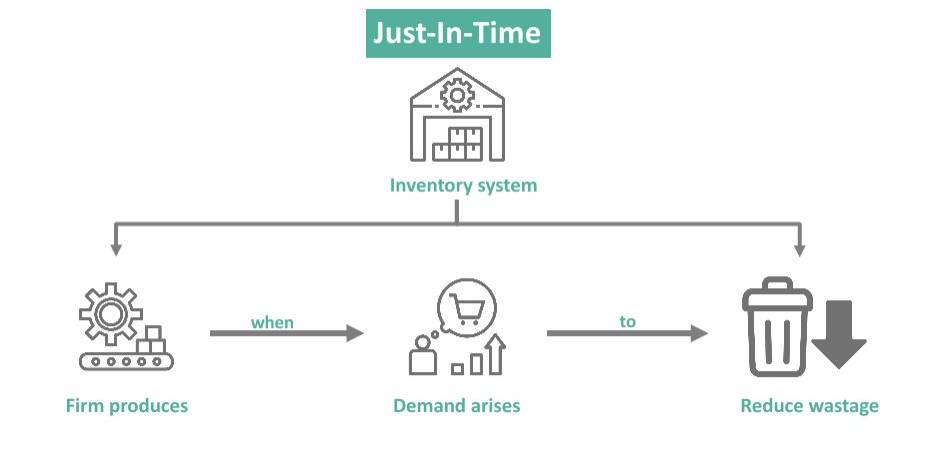

The Just-in-Time (JIT) approach also gained traction among businesses. This strategy, which originated from Japanese manufacturing, focuses on keeping only the inventory you need when you need it. It reduces warehousing costs and minimizes wastage.

This approach’s master is Toyota. The automobile manufacturing titan pioneered the Just-in-Time (JIT) inventory system. They produced vehicles based on real-time demand rather than forecasts, and Toyota significantly minimized its inventory costs. This nimble approach ensures they stay adaptive to market shifts.

But it's not without its challenges – to implement JIT effectively, businesses need a strong relationship with suppliers and ultra-efficient transportation solutions.

To top it off, you should integrate regular inventory audits to make sure that records match actual stock levels. Discrepancies, no matter how minor, cause order imbalances. In the technology age, RFID tags and barcode scanners facilitate these audits and make the process seamless and accurate.

III. Leverage Technology

In our digital age, technology is efficient logistics’s backbone, especially if you’re partnering with third-party logistics providers. You can use automatic container loading systems to help reduce breakdown maintenance and ensure preventive maintenance. This not only trims down logistical expenses but ensures there's no product damage.

Investing in modern supply chain management (SCM) systems is also a no-brainer. While doing so, a proper business proposal and business plan will guide the system’s integrations into your business.

Beyond basic tracking, these systems offer integrations with vendors, deep insights into potential bottlenecks, and even harness artificial intelligence to foresee challenges. Although there's an upfront cost, the long-term savings and efficiency boosts often justify the investment.

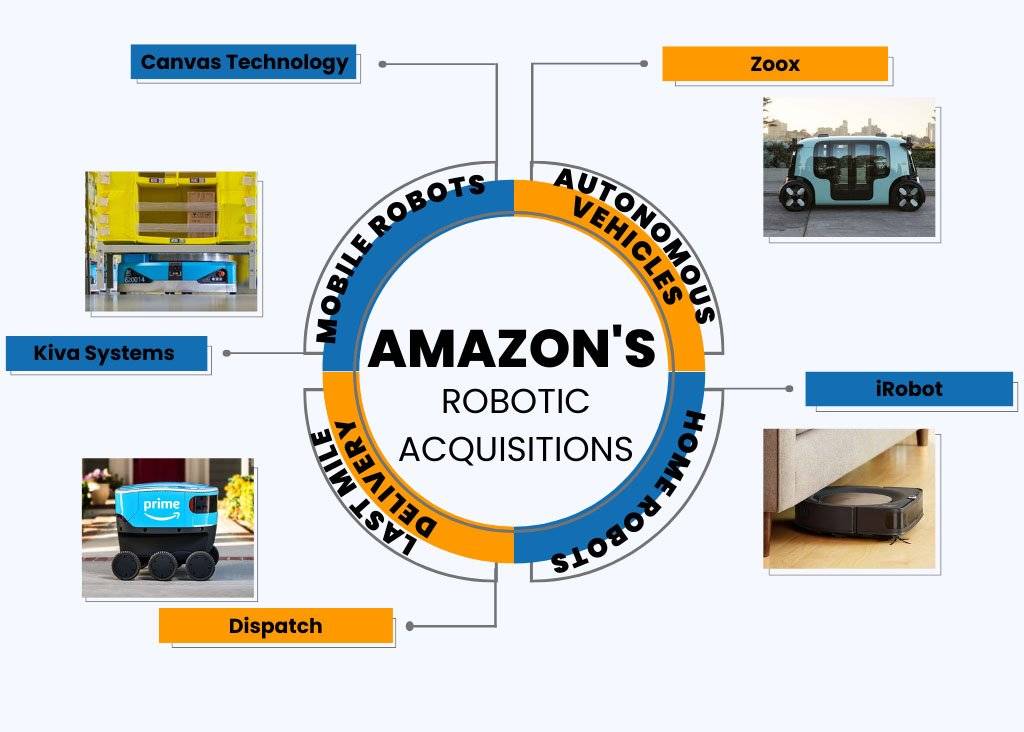

Look at Amazon's innovative technology use. They use Kiva Systems to lead a revolution in warehouse automation. By integrating Kiva robots across its fulfillment centers, Amazon dramatically reduced its "click to ship" cycle time. This efficiency, paired with their sophisticated supply chain software, saved them billions.

Automation is another area that has revolutionized logistics. Whether it's robots that streamline warehouse operations or AI algorithms that optimize routes in real-time, automation reduces human error, accelerates processes, and, in turn, trims costs.

However, the tech landscape is evolving rapidly. You need to stay updated. Regular training sessions ensure your team maximizes the available features and tools and stays ahead so that every dollar spent on tech drives value.

IV. Build Strong Relationships With Suppliers

Behind every successful logistics operation is a web of strong supplier relationships.

Negotiating is an art. It's not about squeezing every penny but finding mutual benefits. Solid relationships might unlock perks like bulk discounts or even flexible payment terms, which can help with cash flow.

Direct logistics costs can also be controlled by negotiating effectively with suppliers. Investing time in understanding the cost control methods suppliers use will help in planning for operating costs.

Consider the specifics: If you're sourcing materials, be it car parts or durable toys for dog training boot camps, you should carefully understand your supplier's capabilities. For instance, if you're running a dog boot camp, you need toys that can withstand intense training.

This requires close collaboration and communication with suppliers to make sure the products meet rigorous standards.

Apple's unparalleled success can partly be attributed to its strong supplier partnerships. By nurturing deep relationships with key players like Foxconn, they ensure a steady product supply, even during peak seasons. This collaboration has kept them on top without excessive costs.

However, these relationships should be nurtured over time with mutual respect and understanding.

Open communication lines can't be overemphasized. Regular check-ins and updates can flag potential supply disruptions early, which can help you adjust your strategies proactively. This proactive approach prevents last-minute scrambles that often result in higher costs.

It’s wise not to put all your eggs in one basket. Diversify your suppliers so that you can reduce dependency on a single entity and ensure your business’s continuity. If one supplier faces issues it’s good to have alternatives so that your supply chain stays intact.

V. Continuously Train Your Team

At its core, logistics are the people who run it daily.

Skill development is a continuous process. Regular training in the latest industry best practices, technologies, and methodologies ensures your team is always equipped to handle challenges efficiently. It's an investment that yields returns in smoother operation forms and cost savings.

You should train them about the importance of safety stocks and the impact of fluctuating fuel consumption on last-mile delivery. When they understand the importance of economical options like selecting the right shipping container, it can have profound effects on your fulfillment costs.

Take Zara, for instance. They constantly invest in training their employees so they're updated with the latest fashion trends and retail strategies. This real-time feedback loop from store employees to designers has cemented Zara's position as a fast fashion leader.

A continuous improvement culture, like promoting feedback and open dialogue, ensures ground-level insights reach decision-makers. The team members often spot inefficiencies or improvement areas firsthand.

Logistics is a dynamic field, with new strategies and tools emerging regularly. Keep the team informed through workshops, seminars, or courses so they don't rely on outdated practices, which could be costlier and less efficient.

Conclusion

Navigating through logistics supplies and managing customer service efficiently ensures customer satisfaction. As you look at cutting costs, don't compromise on quality. Make sure you have enough warehouse space but don't hoard unnecessary safety stocks.

Remember, costs in logistics are variable. There are always methods to reduce these without compromising on the end service. Rather than sticking to one strategy solely, you should be adaptable so you can navigate any unforeseen twists and turns with ease.

Want to expand your horizons into international shipping? Explore SeaRates. Since our launch in 2005, we have been making global shipping simpler and more efficient. Dive into our platform for a smoother cargo transport experience, and take your logistics game to the next level. Ready to set sail? Visit our website here.