Consider a critical vaccine, sensitive to the smallest changes in temperature, making its pivotal journey from the lab to a healthcare facility; its efficacy and the health outcomes of countless individuals hang in the delicate balance of optimal conditions. This is the imperative and intricate world of Cold Chain Logistics, where more than the food supply chain is at stake, but safeguarding life-saving supplies from origin to destination is also the mission.

In this post, we will navigate through the detailed universe of cold chain logistics and refrigerated cargo movement, where temperature stability is paramount and any fluctuation is handled with the utmost priority.

Read on as we explore the technological innovations safeguarding our consumables and ensuring our food and medicines remain potent across vast distances, the obstacles encountered in sustaining such stringent standards, and the forthcoming innovations poised to transform cold chain transport & functions.

Understanding Cold Chain Logistics

Cold chain logistics is a fascinating and complex process that plays an essential role in the global trade of perishable goods. It refers to the supply chain for products needing refrigeration, from food items to pharmaceuticals.

But what makes it tick? The answer lies in maintaining stable temperatures during transport. To do this, cold storage facilities and advanced technologies come into play. They work together to manage temperature requirements within the cold chain.

Role of Temperature Control in Cold Chain Logistics

Maintaining temperature integrity is paramount when handling sensitive cargo like biological samples or medicines that can lose their efficacy if exposed to ambient temperatures.

When it comes to temperature controlled shipping, the use of eutectic plates helps keep shipments cool over long distances while dry ice serves as an excellent coolant for shipping biological cargo at extremely low temperatures. Combined with innovative solutions like solid carbon dioxide (dry ice), these methods help maintain required conditions even on lengthy journeys.

The increasing demand for digital transformation across the industry has also improved the available technology. With advancements such as real-time monitoring systems, managing cold chains has become more accurate than ever before - making sure your steak stays fresh all the way from farm to table.

Implementing Effective Temperature Control Measures

The success of cold chain logistics lies in maintaining optimal temperatures. But how can we achieve this? Let's examine two powerful tools: eutectic plates and dry ice.

Use of Eutectic Plates and Dry Ice in Cold Chain Logistics

Eutectic plates, often filled with gel packs, are the unsung heroes that maintain the temperature range for cold chain logistics. These magic panels freeze goods to their core while preventing unwanted frostbite. Not only do they keep products cool during transport, but also regulate humidity conditions, an overlooked aspect crucial for preserving product quality.

Dry ice is another notable change in the field of cold chain production and distribution. Unlike regular ice, which melts into water, it sublimates directly from solid carbon dioxide into gas, keeping your precious cargo dry and chilled without leaving a watery mess behind.

Cold chains vary greatly; some might need to handle everything in-house while others outsource certain aspects. No matter the approach, these strategies help make sure top-notch quality is maintained until products get to customers.

Overcoming Challenges in Cold Chain Logistics

A cold chain logistics service involves the intricate dance of maintaining a stable temperature for sensitive goods during transport.

The challenges in cold chain logistics are numerous, particularly with international trade and long-distance shipping. Imagine sending biological cargo over vast oceans. It is a complex puzzle when you consider regulatory requirements such as those from the pharmaceutical industry.

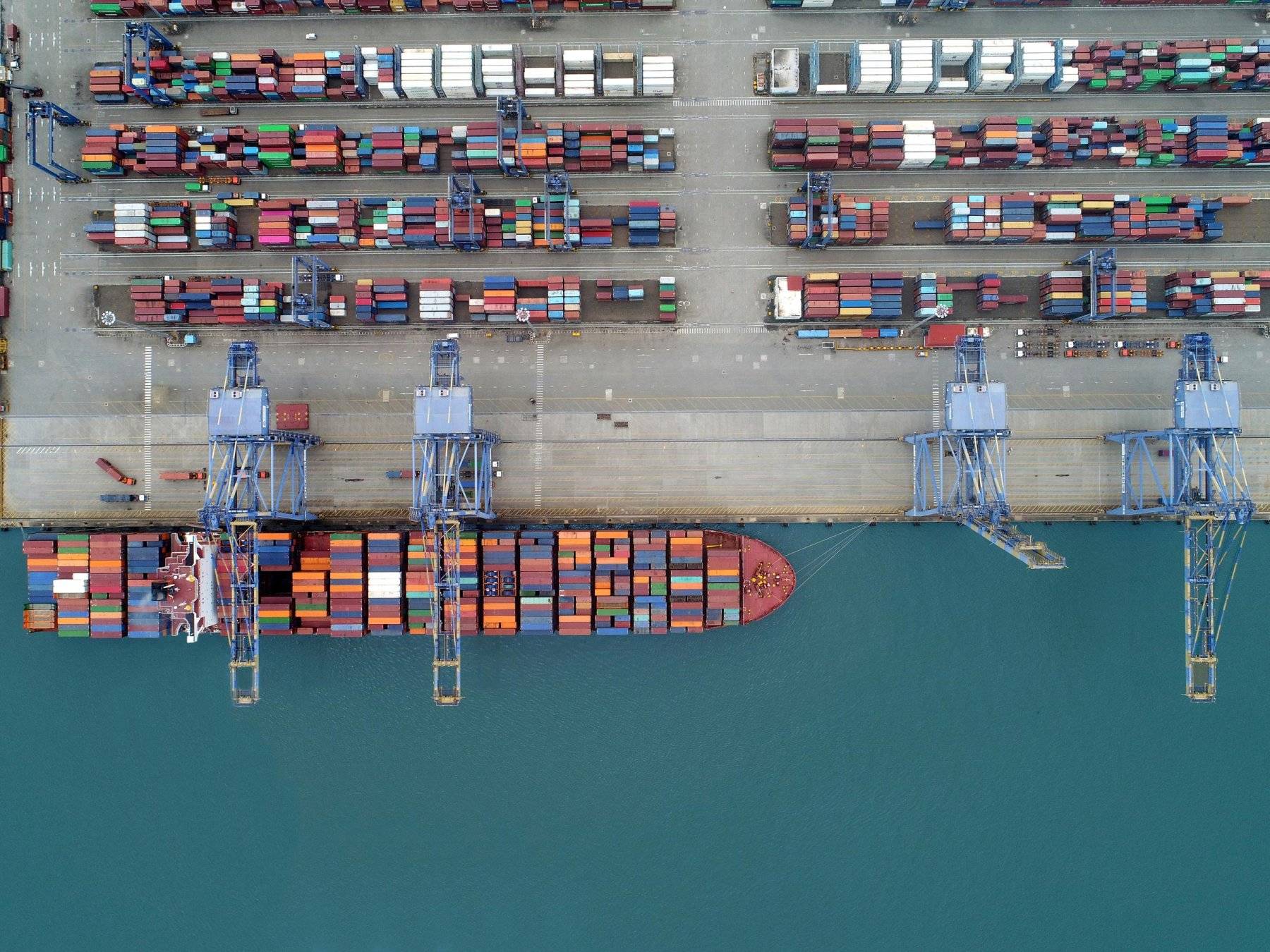

Firms must devise novel solutions to address these difficulties. For instance, using innovative technologies like refrigerated containers can help maintain required temperatures while transporting perishable products across continents or between distant markets.

A crucial aspect is also ensuring safety compliance within industries like pharmaceuticals, where precise temperature control is vital for public health reasons. Inaccurate cold chain processes can lead to product degradation, impacting shelf life and final consumer satisfaction – nobody likes spoiled milk.

One method employed by businesses is real-time monitoring systems, which track ambient temperatures inside containers, allowing adjustments on the fly if needed. These modern solutions help fix problems before they escalate into full-blown crises, keeping our global trade ticking along smoothly.

Technological Innovations in Cold Chain Logistics

The cold chain transport industry has witnessed a technological revolution. Top providers now offer advanced solutions such as refrigerated containers and monitoring systems.

Role of Cold Chain Software and Monitoring Systems

Cold chain software plays an integral part in maintaining the necessary temperature range for transporting perishable goods. These innovative tools give real-time updates on ambient temperatures, allowing for immediate action if fluctuations occur.

Solid carbon dioxide, or dry ice, is another innovation in this field. It helps maintain low temperatures during transit, keeping products fresh over long distances.

The introduction of refrigerated containers has also boosted efficiency within the industry. Designed to keep cargo at a stable temperature regardless of outside conditions, these containers are pivotal for shipping dangerous goods like biological cargo without compromising public health and safety standards.

Technology has transformed cold chain operations by enhancing accuracy and improving delivery times for temperature-sensitive products worldwide. From sophisticated container tracking software to revolutionary packaging techniques with solid carbon dioxide - innovation continues to redefine this crucial sector in global trade.

SeaRates' Solutions for Cold Chain Logistics Challenges

In the complex world of cold chain logistics, SeaRates is a global leader. We have leveraged our extensive expertise to craft efficient solutions for transporting temperature-sensitive cargo.

Take pharmaceutical products, which need strict temperature controls. We use advanced global cold chain distribution networks to ensure their safe transit. These networks maintain optimal conditions during transport and storage stages, keeping these critical items within their required temperature range.

We're proud that our partnership with Novo Nordisk helped them move closer to their goal of going net zero. This successful collaboration underscores our commitment not just to operational efficiency but also to environmental responsibility in global trade.

Navigating the challenges posed by long distances and varying ambient temperatures can be tricky when it comes to perishable goods. But here is where we excel - our leading-edge cold supply chains are designed precisely for this task.

The key is adaptability: Whether dealing with food products or biological cargo requiring a stable environment, we tailor our services based on specific needs. No challenge is too great.

Conclusion

Cold Chain Logistics is a lifeline, ensuring our food stays fresh and medicines potent. It is vital that everyone in the supply chain keeps temperature-sensitive cargo in optimal conditions during transit.

Effective temperature control measures are crucial. Eutectic plates, dry ice - these are not just trending terms but tools in the fight against the heat degradation of precious goods.

The challenges are always present—international trade hurdles, long-distance transport issues; yet with each challenge comes an opportunity for innovation and growth.

Innovative technologies like refrigerated containers and advanced container tracking and monitoring systems have revolutionized cold chain operations. The advantage of digitization across the industry is the ability to ensure we get quality products safely to their final destinations.

Harnessing the expertise of SeaRates to provide reliable answers for transporting temperature-sensitive cargo globally results in Cold Chain Logistics success.

FAQs in Relation to Cold Chain Logistics

What is the cold chain logistics?

Cold chain logistics involves moving temperature-sensitive goods using refrigeration. It is vital in industries like food, pharmaceuticals, and chemicals.

What is an example of a cold chain logistics?

An example might be shipping fresh produce from California to New York while maintaining optimal temperatures during transport.

What are the 2 types of cold chain?

The two main types are passive and active. Passive uses pre-cooled materials; active employs powered cooling systems.

What are the 3 main components of cold chain?

The three key parts: refrigerated storage, transportation with controlled temperatures (like trucks or planes), and lastly, reliable monitoring systems for temperature control.