When it comes to shipping industrial equipment, the challenges are unique and non-standard. Because they're engineered to function optimally in one environment, these machines can't be broken down into smaller components (unless you get an expert), loaded onto a standard pallet, or shipped in a standard container. So, you’ll need a specialist that understands your load and how to handle it for the best results.

Shipping heavy equipment can be an intimidating task. Many variables are involved in shipping any item, so it can become overwhelming. Luckily, some freight companies specialize in this industry and can help you with all your needs on shipping heavy equipment.

Most people wonder how they can ship their heavy machinery. For some, it can be a painful process if you don't know what you're doing. So, here is a guide to help you ship heavy equipment like bulldozers, excavators, cranes, and lifts easily.

Understanding Different Shipping Methods

The most important aspect of shipping machinery is deciding the best method to use. You can ship your heavy equipment in several ways, but your cargo's shape and size will still dictate the most appropriate way. The following are the most common methods of shipping heavy equipment that freight companies use:

LoLo (Lift On/Lift Off)

The lift on/lift off shipping method uses a crane to lift equipment on and off a shipping vessel. It's considered one of the simplest heavy machinery shipping methods.

LoLo ships can carry large-capacity containers. As such, this method can offer efficient transport of your cargo.

Because these ships use cranes to load and offload cargo, they may require a specialized crew to operate them. This may mean additional cost implications.

Flat Rack Method

A flat rack comes with only support posts on the ends. This way, your equipment can be loaded from the top or sides. This may be the best way to ship your cargo if you have large equipment that cannot fit into a standard container.

Flat rack beds come in standard container sizes of 20 ft and 40 ft. A single flat rack can carry up to 48,000 lbs of cargo. It’s perfect for oversized freight and equipment that sticks out when in transit. Most flat racks also have forklifts or cranes that load heavy cargo on and off the vessel.

As with any shipping method, flat racks have disadvantages and advantages. The most significant advantage of a flat rack container is that you can use it to carry out-of-gauge equipment that needs loading from the top or side. As mentioned, flat racks only have stability walls on their ends, so you risk exposure to sea elements. Your freight can also be tarped, but it does not provide the same protection a container or dry van trailer would.

Container Shipping

The container shipping method is one of the most usual methods international heavy machinery manufacturers use to export their products. It allows for easy loading and offloading of cargo on and off the containers. However, there are instances where this may not be the most viable method to use. For one, large pieces of equipment may not fit into a standard container. In such a case, you may be forced to disassemble your equipment so that it can fit into the container.

Still, container shipping may be the most common way to transport your freight, but it has its pros and cons. The best thing about shipping container transport is how easy it is to haul equipment. At the same time, its biggest flaw is how much time and labor it takes to dismantle the equipment and build it back up.

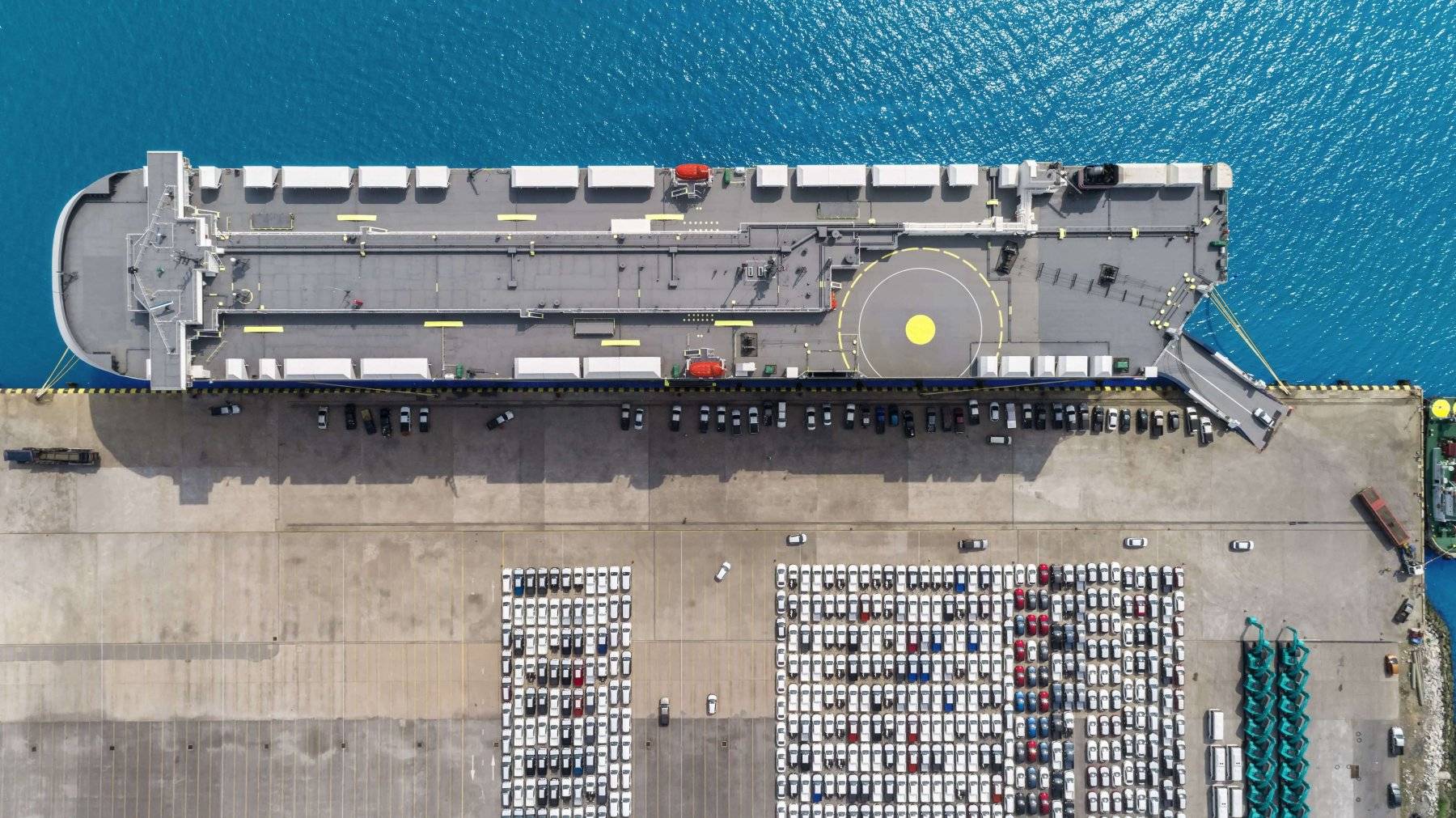

Roll-On/Roll-Off (RoRo)

Roll on/Roll off is considered the simplest method of shipping machinery. RoRo ships are specially designed to ship wheeled freight like trucks, railroad cars, buses, and cars. The design allows cargos to be driven onto and off the vessel using their own wheels.

As mentioned, the shipping industry measures its cargo by metric tonnes. However, RoRo freight uses lanes in meters (LIMS) to measure its freight capacity. The load is calculated by multiplying the cargo's breadth and length by the total number of decks on the vessel.

Again, as with any method, this has advantages and disadvantages. The best thing about RoRo is that there's no need for a specialized crew or equipment for loading and offloading these cargos. Its biggest drawback, however, is that it can be expensive, especially if importing several machines. This is because it does not allow for stacking, so you can't make maximum use of space.

Heavy Equipment Shipping Cost

Many aspects affect the cost of shipping heavy equipment. The cost of insurance, broker fees, packaging materials, mileage, and tracking contribute to overhead costs. However, the most important factors are as follows:

Density

The shipping industry uses density, the size and weight of the cargo, as a standard gauge measurement of machinery. Density is the space on which equipment sits and occupies, and it's as essential to shippers as its weight. Your equipment's density will dictate every aspect of your shipping needs: shipping method, price, and ease and speed of delivery.

Standard shipping practices are sometimes set aside when it comes to heavy equipment. It's done to acclimate the peculiarities of these payloads. It doesn't matter if it is a tractor, excavator, aircraft engine, or even a boat; your carrier must make exceptions to your heavy load's unique shape, size, and weight.

The density of your heavy equipment will account for most of its calculated shipping expenses. This includes the cost of picking it up, handling, and delivery. It will also determine the most convenient shipping method for your large equipment.

Insurance

Freight insurance cover is necessary when shipping heavy equipment. It’s meant to cover any damage that may occur while the shipment is on its way to you. Most shipping companies will offer a basic insurance policy on anything they transport, but it may not be enough. You should also remember that these policies do not cover damages caused by acts of God.

Shipping heavy equipment comes with many risks for the shipment and the hauler. Hence, you may need better insurance coverage than just the basic policy provided by the carriers. As you may have learned, heavy freight shipping is much more complicated compared to simple container shipping. This is because of its size and weight that demand more caution.

You can buy a third-party insurance policy for your cargo plus better covers from most freight companies. Of course, the cost of shipping your equipment will increase. Still, it can be the difference between a total loss and recovery in case of an accident.

Freight Brokers

Heavy equipment shipping is a complicated process. Thus, you may be required to consult a licensed and experienced freight broker. This is a third-party specialist who links shippers with haulers.

Most shippers would underestimate the role of a freight broker, and they may even disregard the need for them. Sadly, that can be costly on their end because a good broker can be worthwhile as the freight they are hoping to ship.

Freight brokers are industry experts with years of experience. They maintain a vast web of carriers to enable convenient shipping worldwide. When it comes to moving heavy machines, each one may have its specifications. In that case, you may want to engage the services of a broker whose education, experience, and expertise will come in handy. Not only do they link you with the most reputable carrier, but it's also the surest way to ensure someone prioritizes your conveying needs. So, your equipment will get to its destination on time.

Priority

How soon do you want your industrial machinery at its destination? You should prepare to pay for the services if you are looking for urgent shipping for your heavy machinery. Indeed, urgent shipping can be expensive. However, there are ways you can fulfill these rush orders in a cost-effective and timely manner.

Naturally, this may require employing the services of an expert third-party logistics firm. They'll help get your cargo where it needs to go. Yet the truth is, there's no helpful guide that can prepare you in time to meet a last-minute hauling deadline. Yet if you're looking for solutions and want to expedite priority shipments, you should consider contacting a reputable freight broker.

Choosing A Shipping Company

At this point, you already know which shipping method may suit you better based on your cargo. So, the next thing will be to contact a freight shipping company.

You shouldn't lose sleep because of stress related to shipping your equipment. It's necessary to hire a professional shipping company that can handle everything from loading to unloading and provide coverage in case anything goes wrong on the trip. A freight service can help you avoid shipping problems because they know the system and are experts in the industry. Here are key considerations when picking a shipping company for heavy equipment:

- Ask for referrals from friends and family members who have used different companies in the past. The idea is to work with a company that's experienced and reliable.

- Distance: How far does your heavy equipment need to travel? How far away is the nearest port? What type of transportation is available? These are things that may affect the cost of moving your cargo.

- Size: How large is your heaviest piece of equipment? Is it too big for one truck or two smaller ones? Can it fit in a single container or multiple containers?

- Find out if they offer insurance. What happens if something goes wrong? How much will it cost? Make sure their insurance covers your items. It may also be worth looking into additional coverage, such as liability and property damage.

- Ask how long it takes them to load and unload equipment. It helps if they can estimate how long it will take; this way, you’ll know if there's enough time before your shipment arrives to ensure everything goes smoothly.

- Find out how much it costs for each trip. Shipping companies usually charge by pound or cubic foot. Don't forget to ask what type of packaging they use when packing your load for shipping and their rates per pound or cubic foot.

Heavy Equipment Shipping Requirements

You must note several factors before you can ship your heavy equipment. The type of cargo you want to ship will dictate the most convenient method to use. Still, more than hauling, you must consider the following:

- What is the most convenient way for it to be shipped? Is it by air, sea, or combination?

- Are there special permits and licenses needed for the equipment you are shipping? Different countries have different requirements.

- Will your equipment require bracing and blocking?

- How long will you need to prepare the destination point before you can receive the cargo?

- Will your heavy equipment need a piece of specialized equipment to load and offload? Ensure that you know this information and inform the relevant parties.

- There are different ways to pack cargo, so ensure it’s packaged correctly, depending on your equipment. Is it something that can be boxed, tarped, or palletized? Again, make sure to let your shipping company know it is packaged.

- If your equipment needs any special preparation before loading, ensure that it's done right. This will help prevent and minimize any damage.

- From the original point to the docks and the final destination, and even in between these points, hauling your equipment may involve trucks. Think about what might happen before and after reaching the ports. Will the equipment defy dangerous terrains?

- Is there any special packaging needed to protect the cargo from corrosion? If so, make sure to inform the shipping company.

If you are unsure how to go about all these, refer to your user's manual for shipping recommendations.

Information To Give The Shipping Company

The shipping industry is one of the key industries in the world, but it's also one of the most complex. Because of its nature, it's easy to make mistakes that can be costly.

The first thing is to ensure that the shipping company has all the relevant information. You should make sure that the shipment information matches the equipment being hauled.

Incorrect details may end up costing you much more. To prevent this and to ensure that your payload is secure, you must provide the shipping company with these details:

- Equipment specs. Provide the exact brand and model of the heavy machine. If you don't have the correct info, do proper research to ensure you know your equipment's specs.

- If your equipment has been modified, you must provide the exact details.

- What are your machine's exact dimensions? Make sure to provide their actual size and weight.

- You may need to supplement the carrier's insurance coverage. Therefore, you must know the exact details of your hauler's insurance coverage.

- Take a picture of your heavy equipment from different angles. This is a visual reference that can give the hauling company an idea of the equipment.

Conclusion

Acquiring an industrial machine can undoubtedly be expensive. Shipping it to your destination can be even more costly. In addition, there are many variables you must keep in mind. Anything that could go wrong can go wrong. However, there are things you can do to ensure that your equipment reaches its destination in one piece.

Whether it is your first time or not, it’s advisable to employ the services of a third-party expert freight service. You can take advantage of their knowledge and expertise in shipping your equipment. Besides, knowing that professionals are handling your shipment will give you peace of mind.